Driveshaft Materials

When you need a driveshaft that is light weight, can handle higher torque loads and can give you a nice polished finish, then consider an Action Machine aluminum driveshaft. The Action Machine aluminum driveshaft is ideally suited for street rods, show cars, race cars and as OEM aluminum replacements. While other driveline shops may use .065" wall or .083" wall tubing for their aluminum driveshafts, our volume purchasing allows us to use .125" wall tube for the same price as the thinner tube. You have the best in aluminum performance no matter your application.

Precise construction is critical to a well performing driveshaft - especially for aluminum. Poor quality components, tubing even slightly out of tolerance or a poorly balanced driveshaft can all lead to major vibration problems or worse – a total driveline failure. Action Machine is one of a handful of companies in the world whose commitment to quality drove us to complete Spicer’s intensive dynamic reverse torsion fatigue testing requirements. Our aluminum driveshafts are Dana Spicer tested for torsional load strength, weld penetration/quality, and overall manufacturing quality. Look at some of our competitors and it will be easy to see that you can pay more an aluminum driveshaft. But a higher price does not mean a better shaft. Our quality is second to none. We've done the testing to prove it.

Our aluminum driveshafts are made with .125" wall 6061 – T6 DOM aluminum tube. This provides the optimal combination of aluminum quality, torsional strength, long term durability and clean finish. All yokes are forged using the same 6061—T6 aluminum and individually machined to attain the best fit and performance. We never use cast aluminum. Our aluminum shafts come in 3", 3.5", 4", 4.5" and 5” OD tubing.

Consider one of our 4 to 5" diameter aluminum driveshafts to replace your OEM pick-up truck driveshaft. The lighter weight allows the aluminum shaft to be longer and cover the same distance as a steel 2 piece shaft. The one piece aluminum shaft eliminates the common problems of vibration and constantly wearing center bearings associated with some trucks. Call us today for your OEM replacement aluminum driveshaft for your Dodge, Ford, or Chevrolet truck.

Action Machine custom drive shafts are built to meet your specific needs and built to last. Tubing material and thickness, U Joint type, and component selection can all be varied to match your driving conditions and vehicle performance. Driveshafts are checked in special computer software to ensure that shaft design, dimensions, and critical speeds will suit your application. If it won’t work, we’ll tell you "No" before we’ll sell you something that we know will break.

Before any shaft is balanced, the tube is straightened to tolerances that are less than half that of OEM specs. With a straighter tube, the driveshaft will spin closer to its exact centerline so it needs less balance weight and minimizes the possibility for drive shaft “whip” at higher RPMs. Balancing the shaft is then easy with straight tube. Our shafts are high speed balanced on the latest driveline manufacturing equipment with balance weight allowances far less than OEM specs.

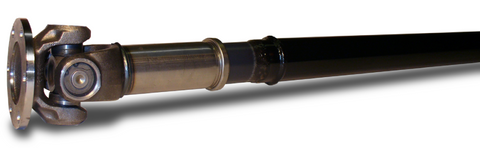

All steel driveshafts are made from the finest driveline quality tubing which makes our driveshaft stronger and straighter from the start compared to regular cold rolled tubing. Steel is our most popular material choice due to its versatility, high strength and economical price.

Our high strength steel driveshafts can be custom designed for:

- Replacement or repair of your original drive shaft.

- Performance, street rods, and circle track cars.

- Light & Medium Duty Trucks for box / flat bed trucks, motor homes and vans.

- Heavy Duty Truck and semi diesel tractor applications.

- Multiple piece driveshafts for trucks, vans and motor homes.

- 4 x 4 trucks.

Remember that we can help you upgrade the performance of your driveshaft by increasing the U-Joint series and tubing size.